bphillips921

- 8

- 1

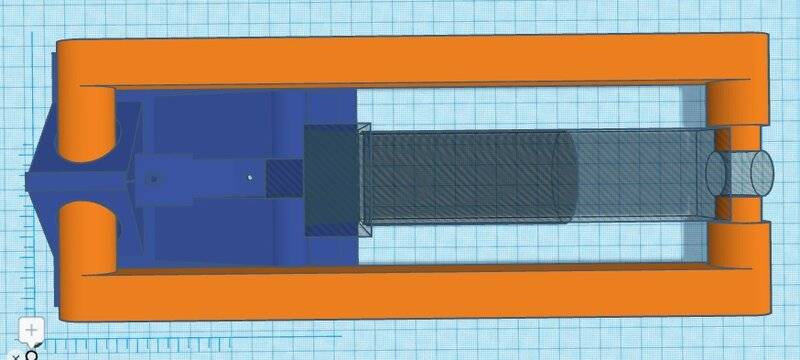

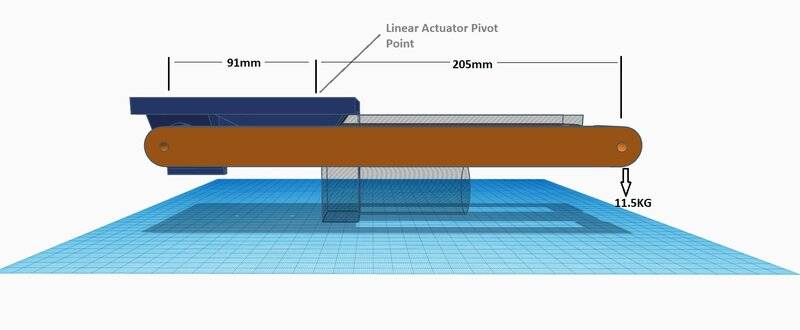

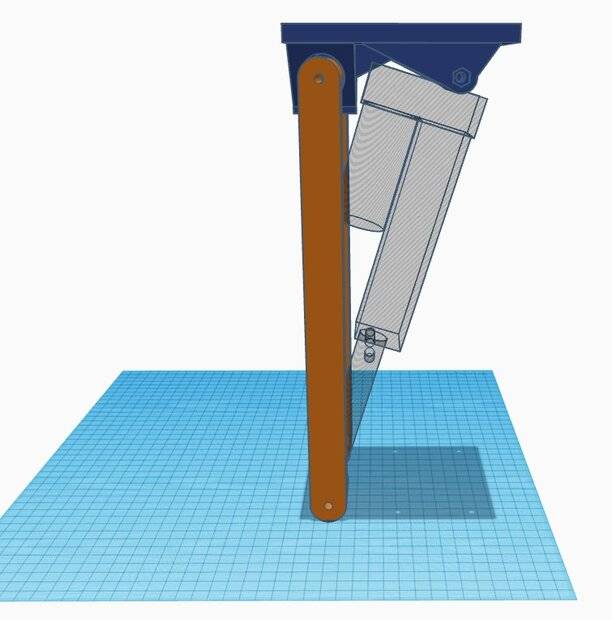

I'm designing a pivot lift system to lift my movie projector up when not in use. I've designed the parts and begun 3D printing, but am concerned that the 3D print won't be strong enough, so I may bite the bullet and have the parts CNC machined. If I do that I want to be certain that I have the correct linear actuator since changing that could change the parts. I can't figure out how to calculate the force the linear actuator needs to lift my 11.5KG projector from a dropped position rotated 90 degrees up to the ceiling. My CAD design is below with the dimensions and the weight of the projector. I bought a 750N (160lbs) 100mm stroke linear actuator, will this be enough? Any guidance would be appreciated!

Bottom View (retracted)

Side View (retracted)

Side view (Extended)

Bottom View (retracted)

Side View (retracted)

Side view (Extended)