thdwngus

- 2

- 0

- TL;DR Summary

- torsion spring design to open a lid with catch

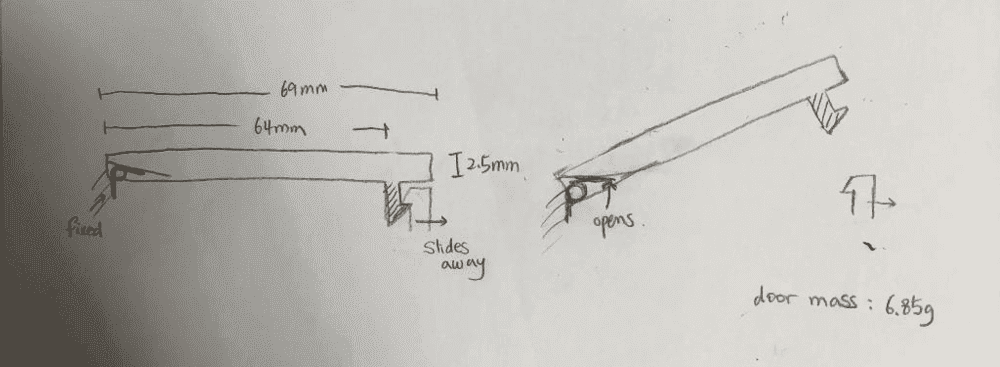

I am trying to design a small box with a hinged door/lid that opens with a torsion spring.

When closed, the door will latch onto a mechanism where the open button is, and when the button is pressed this mechanism will slide away, removing the latch out of the way so that the door can fly open. This is a side view of a hinged door with torsion spring.

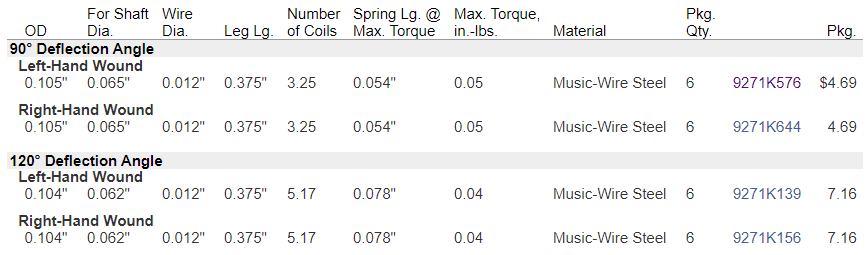

The torsion spring will be preloaded so that it can lift up the door when released, and the door is to open until it reaches a physical stop. I am currently trying to design around a 90 degree or 120 degree torsion spring on both ends of the lid:

It'd be great if I could get any guidance on following questions:

- When in closed state, how much force is exerted on the colored hook? I want to know if the colored hook would fail due to the loaded force of the spring, and would want to prevent that.

- What design specification of the torsion spring is needed for the spring to open the door?

Door mass is 6.85g, please let me know if there are any other information needed. Thanks!

When closed, the door will latch onto a mechanism where the open button is, and when the button is pressed this mechanism will slide away, removing the latch out of the way so that the door can fly open. This is a side view of a hinged door with torsion spring.

The torsion spring will be preloaded so that it can lift up the door when released, and the door is to open until it reaches a physical stop. I am currently trying to design around a 90 degree or 120 degree torsion spring on both ends of the lid:

It'd be great if I could get any guidance on following questions:

- When in closed state, how much force is exerted on the colored hook? I want to know if the colored hook would fail due to the loaded force of the spring, and would want to prevent that.

- What design specification of the torsion spring is needed for the spring to open the door?

Door mass is 6.85g, please let me know if there are any other information needed. Thanks!