- #246

spork

- 203

- 0

To first order approximation we run about 5 degrees angle of attack at all stations of the blade at our design point.

Redbelly98 said:The two posts were automatically put in moderation, meaning they were not visible except to forum Mentors -- we're not sure why this happened.

I have made the posts visible again, here are direct links:

Post # 208

https://www.physicsforums.com/showthread.php?p=3427707"

RonL said:Llyricist did a beautiful job with his posts.

Ron

spork said:Yes he did. He's also done some great analysis and some really nice animations.

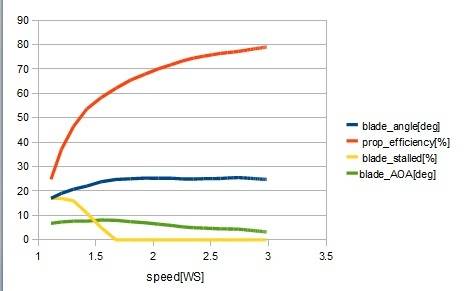

OmCheeto said:From A.T.'s images on https://www.physicsforums.com/showpost.php?p=3352297&postcount=51", there is the following graph:

It shows a blade_angle(deg) of from ~17 to ~26 degrees

It also lists a blade_AOA(deg) of from ~9 to ~4 degrees

Yes, in the propeller geometry the angle of incidence (deg) at 0.75 radius corresponds to my blade_angle. But the variable propeller pitch can offset the angle of incidence along the blade by some number.OmCheeto said:Post #208 seemed to have some very strange data. The radius went up, and then the radius went down, whilst the incidence went down.

Post #230 seemed to make more sense, as the angle of incidence minimized at ~20.6 degrees. More in line with A.T.'s "blade angle".

Better perspective:OmCheeto said:The image of the prop on the Discover Channel (post #75) makes it look as there is almost no twist at all, which seems to contradict Llyricist's numbers of from 80 to 20 degrees from axis to tip end.

A propeller uses an AOA versus prop disk that decreases as radius increases, normally set so that the propeller pitch (the effective advanced distance per revolution) is the same at all radius (except for the hub).A.T. said:variable propeller pitch

RonL said:If it has not already been considered, the building of counter rotating props will eliminate some torque problems, double the math fun and maybe add just a little more efficiency. Make the lead prop about 10% smaller than the following prop, then consider a slightly adjustable mast that let's angle be adjusted (a little like timing a brushed electric motor). Just a couple of quick thoughts.

Ron

OmCheeto said:Oh dear hey-Zeus...

Dear Ron,

I'm trying to simplify the math, not make it more complicated.

sincerely,

Om

spork said:I designed and built the thing, and you've lost me. What heat is being converted to work?

Yes he did. He's also done some great analysis and some really nice animations.

A summary of earlier posts.RonL said:Here is what my mind is seeing, the weight of the cart and it's motion is converted into energy to drive the propeller.

RonL said:In my thoughts (within reason) a heavier cart might actually produce a stronger energy transfer, ...

The offset wheelbase was done to widen the wheelbase on the left as roll prevention from the counter clockwise torque from the air. The wheelbase could have been extended equally on both sides and would provide the same roll prevention (actually a tiny bit more due to the small amount of mass in the wheel moved to the right). One of the posts mentioned that the wheelbase was too close to the legal limit on width for a towed vehicle, and another post mentioned that the right axle wasn't extended simply because it wasn't needed.OmCheeto said:Ok, I simplified the FBD to the point where I hope those like me can see where the offset wheelbase comes from.

mender said:I thought that one of the main reasons was to equalize the dynamic load on the rear tires for better traction and more even wear.

mender said:I thought that one of the main reasons was to equalize the dynamic load on the rear tires for better traction and more even wear.

RonL said:Omcheeto's drawing has the qualities of a true Professor.

Ron

Must have missed that!ThinAirDesign said:While those were side bennies, the sole reason was with our higher than expected efficiencies (and thus speeds) we almost tipped it over in Ivanpah.

JB

mender said:Must have missed that!

(edit)

ThinAirDesign said:Perhaps -- but it's still quite nebulous at best and most likely just plain wrong.

JB

ThinAirDesign said:Perhaps -- but it's still quite nebulous at best and most likely just plain wrong.

JB

RonL said:Best wishes

Ron

Thanks, I wasn't sure as I thought the drawing was more clear than my commentsThinAirDesign said:Ron, no offense was taken and I apologize if it appeared so. I was merely commenting on the fact that without clearer definitions, Om's drawing was rather ambiguous.

As to the wheel RPMs that you mentioned, there is no differential in the BB and thus under most normal circumstances the RPMs will match exactly. There are ratchets on the drive axle which allow us to maneuver the cart around without lockup, but again this in straight operation will not allow one driving wheel to rotate faster than the other.

I love skid steers (I own a tracked version - ASV RC-85).

JB

RonL said:I did look up the machine you mentioned, it looks like a really productive unit.

I'll keep a watch for new and improved progress in the wind machines.

spork said:I can't speak to how productive it it - but it's a friggin' blast to drive it up and down steep slopes in the woods!

I posted an update to our blog in the last day or two ( www.fasterthanthewind.org ). I've got 4 more days worth of glassing the turbine blades (final coat) before finishing and painting. Then I've got a bit of transmission work to do. As you may have guessed we're not doing anything like the pace we did last year. JB is on the road full-time, and I'm squeezing my efforts in between work and flying. But there's MUCH less to do. I still hope to do some runs in the next several weeks.

Will you post the blade geometry anytime soon?spork said:I posted an update to our blog in the last day or two ( www.fasterthanthewind.org ). I've got 4 more days worth of glassing the turbine blades (final coat) before finishing and painting.

A.T. said:Will you post the blade geometry anytime soon?

chingel said:I think it is important to understand that it's not just that the propeller is driven by the wheels, it's that if you engage the propeller the wind starts pushing harder on the propeller and the extra wind push drives it forward.

Comparing energy with a force makes no sense.chingel said:...it will use as much energy as it puts drag on the wheels,...

It does matter. Without multiplying the force, the propeller thrust cannot be greater than the wheel drag.chingel said:...no matter if you multiply the force or not,...

spork said:I'd be happy to. I didn't realize anyone wanted to see it.

c Upwind Car SJM 2X 10 mph wind

vc=(2.0+1)*10*1.467 !vo (f/s)

omega=150 !RPM

rho=.00226 !Density (slug/ft^3)1500 ft MSL

vsnd=1116.5 ! Speed of sound (f/s)

rt=9.25 !Tip radius (ft)

rh=0.5 !Hub radius (ft)

nblade=2 !Blade number

ao=5.73 !Lift curve slope of 2-d section

apzl=-5.0 !zero lift angle of attack (deg)

ld=67 !Section max L/D (6412 @350000 Re)

cl=0.9 !CL at max L/D

! Thrust= 149.975052(lbs) Torque= 351.829559(ft-lb) Power= 10.0482292(HP)

! etat= 0.837301373

rad(ft) chord(ft) Beta(deg) thick(%)

0.937500 1.015620 73.071310 18.490000

...

9.162500 0.178680 19.215650 12.000000

spork said:I'd be happy to. I didn't realize anyone wanted to see it.

c Upwind Car SJM 2X 10 mph wind

A.T. said:Thanks. I just tested it quickly. And in theory it looks like you could reach 2x with:

transmission eff: 0.93

aero drag coefficient: 0.22

rolling drag coefficient: 0.01

frontal area[m^2]: 1.8

mass[kg]: 295