xkcda

- 7

- 0

TL;DR Summary: I think A is an non inertial reference frame.So how can I measure kinetic energy about it?

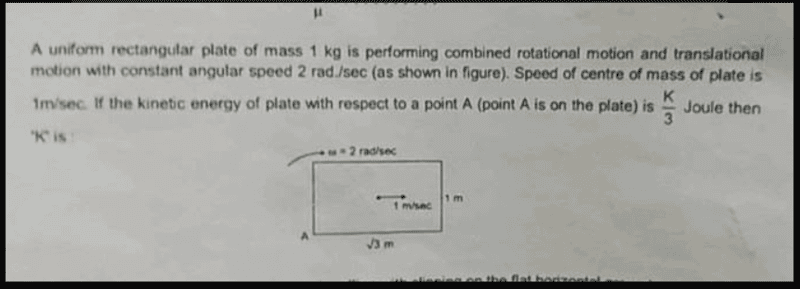

I found a solution to the problem which states that Kinetic Energy about A= (Moment of Inertia about an axis passing through A*Angular Velocity^2)/2+(Mass*Velocity^2)/2 .Thus K=9.5.Can anyone please show me the derivation of this formula?

I found a solution to the problem which states that Kinetic Energy about A= (Moment of Inertia about an axis passing through A*Angular Velocity^2)/2+(Mass*Velocity^2)/2 .Thus K=9.5.Can anyone please show me the derivation of this formula?

Last edited: